OpenTherm Thermostat

Posted on Tuesday, July 17, 2018 at 12:00 AM, 92378 views

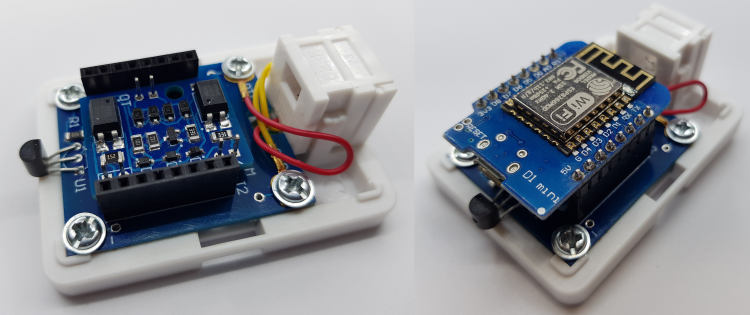

OpenTherm Thermostat is based on OpenTherm Adapter, OpenTherm Library and ESP8266 controller (WeMos D1 Mini).

So you can control your boiler remotely over WiFi via your smartphone.

Using OpenTherm protocol you will be able to:

- get boiler status

- set water temperature

- switch on/off central heating

- switch on/off hot water

- get gas modulation level

- ...and many other commands supported by OpenTherm protocol

Assembled OpenTherm Adapter + Shield:

To Buy Assembled OpenTherm Adapter + Shield (to stack WeMos D1 mini) please navigate to the Shop page or buy it here:

In addition to remote control feature there are much more benefits of using OpenTherm thermostat:

- modulation increases the efficiency of the heating system, reduces environmental effects, as well as increases comfort

- increases the life of the boiler, reduces boiler start/stops

- can provide diagnostic information / boiler errors / fault codes

- lowers fuel bills

To build simple interface between boiler and ESP8266 controller I decided to make stackable OpenTherm Shield compatible with OpenTherm Adapter.

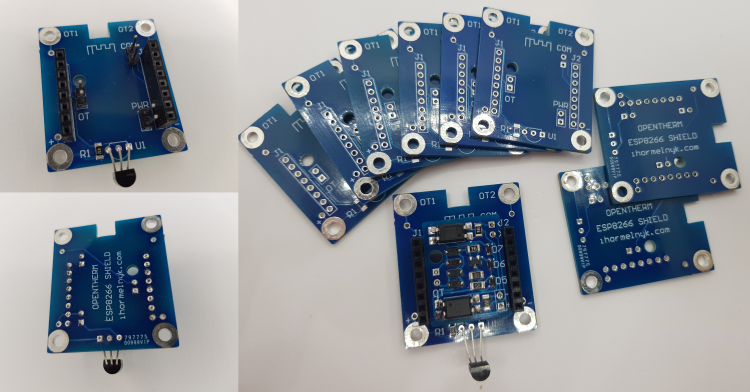

OpenTherm Shield:

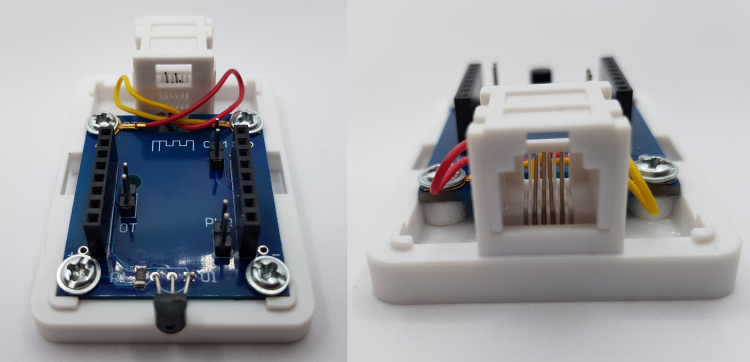

I used RJ12 phone socket as enclosure for OpenTherm Thermostat and to simplify connection to boiler. Made two holes for micro USB charger and for WeMos D1 Mini led. Also I rearranged inner screw connectors. As temperature sensor I used DS18B20, because its small, accurate and easy to use.

Thermostat enclosure:

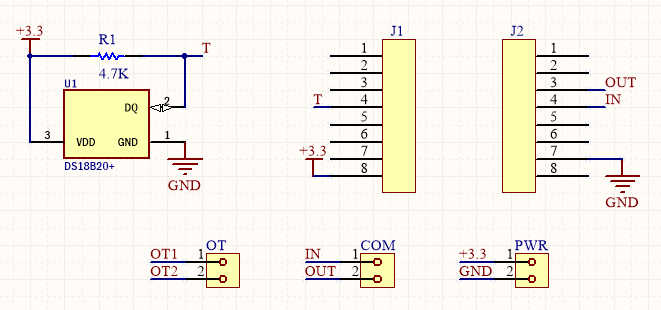

Schematic:

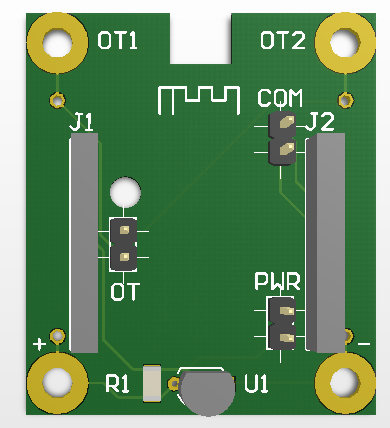

PCB:

Hardware:

- DS18B20 Temerature Sensor 1$

- 8 Pin 2.54mm Stackable Female Pin Header x 2 1$

- 2 Pin 2.54mm Male Single Row Header x 3 0.30$

- 1/4 Watt 5% Resistor 4k7 Ohm 0.01$

- WeMos D1 mini 5$

- OpenTherm Adapter 15$

- EMT Electronics RJ12 Phone Socket Enclosure 1$

Software:

- Arduino Software (IDE) + ESP8266 Board Addon

- Dallas Temperature Library

- Arduino/ESP8266 OpenTherm Library

- Simple OpenTherm Thermostat Sketch

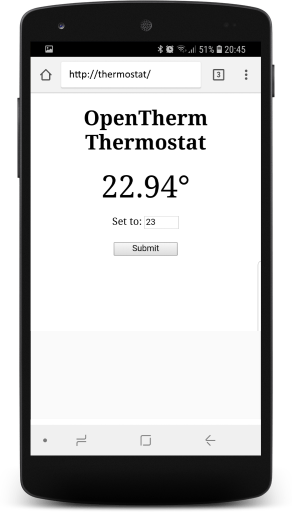

Smartphone Web Interface:

Sample Code:

#include <ESP8266WiFi.h>

#include <WiFiClient.h>

#include <ESP8266WebServer.h>

#include <ESP8266mDNS.h>

#include <OneWire.h>

#include <DallasTemperature.h>

#include <OpenTherm.h>

//OpenTherm input and output wires connected to 4 and 5 pins on the OpenTherm Shield

const int inPin = 4;

const int outPin = 5;

//Data wire is connected to 14 pin on the OpenTherm Shield

#define ONE_WIRE_BUS 14

const char* ssid = "Please specify your WIFI SSID";

const char* password = "Please specify your WIFI password";

ESP8266WebServer server(80);

OneWire oneWire(ONE_WIRE_BUS);

DallasTemperature sensors(&oneWire);

OpenTherm ot(inPin, outPin);

float sp = 23, //set point

pv = 0, //current temperature

pv_last = 0, //prior temperature

ierr = 0, //integral error

dt = 0, //time between measurements

op = 0; //PID controller output

unsigned long ts = 0, new_ts = 0; //timestamp

const char HTTP_HTML[] PROGMEM = "<!DOCTYPE html>\

<html>\

<head>\

<meta name=\"viewport\" content=\"width=device-width, initial-scale=1\">\

<script>\

window.setInterval(\"update()\", 2000);\

function update(){\

var xhr=new XMLHttpRequest();\

xhr.open(\"GET\", \"/temp\", true);\

xhr.onreadystatechange = function () {\

if (xhr.readyState != XMLHttpRequest.DONE || xhr.status != 200) return;\

document.getElementById('temp').innerHTML=xhr.responseText;\

};\

xhr.send();\

}\

</script>\

</head>\

<body style=\"text-align:center\">\

<h1>OpenTherm Thermostat</h1>\

<font size=\"7\"><span id=\"temp\">{0}</span>°</font>\

<p>\

<form method=\"post\">\

Set to: <input type=\"text\" name=\"sp\" value=\"{1}\" style=\"width:50px\"><br/><br/>\

<input type=\"submit\" style=\"width:100px\">\

<form>\

</p>\

</body>\

</html>";

void ICACHE_RAM_ATTR handleInterrupt() {

ot.handleInterrupt();

}

float getTemp() {

return sensors.getTempCByIndex(0);

}

float pid(float sp, float pv, float pv_last, float& ierr, float dt) {

float Kc = 10.0; // K / %Heater

float tauI = 50.0; // sec

float tauD = 1.0; // sec

// PID coefficients

float KP = Kc;

float KI = Kc / tauI;

float KD = Kc*tauD;

// upper and lower bounds on heater level

float ophi = 100;

float oplo = 0;

// calculate the error

float error = sp - pv;

// calculate the integral error

ierr = ierr + KI * error * dt;

// calculate the measurement derivative

float dpv = (pv - pv_last) / dt;

// calculate the PID output

float P = KP * error; //proportional contribution

float I = ierr; //integral contribution

float D = -KD * dpv; //derivative contribution

float op = P + I + D;

// implement anti-reset windup

if ((op < oplo) || (op > ophi)) {

I = I - KI * error * dt;

// clip output

op = max(oplo, min(ophi, op));

}

ierr = I;

Serial.println("sp="+String(sp) + " pv=" + String(pv) + " dt=" + String(dt) + " op=" + String(op) + " P=" + String(P) + " I=" + String(I) + " D=" + String(D));

return op;

}

void handleRoot() {

digitalWrite(BUILTIN_LED, 1);

if (server.method() == HTTP_POST) {

for (uint8_t i = 0; i<server.args(); i++) {

if (server.argName(i) == "sp") {

sp = server.arg(i).toFloat();

}

}

}

String page = FPSTR(HTTP_HTML);

page.replace("{0}", String(getTemp()));

page.replace("{1}", String((int)sp));

server.send(200, "text/html", page);

digitalWrite(BUILTIN_LED, 0);

}

void handleGetTemp() {

digitalWrite(BUILTIN_LED, 1);

server.send(200, "text/plain", String(getTemp()));

digitalWrite(BUILTIN_LED, 0);

}

void setup(void) {

pinMode(BUILTIN_LED, OUTPUT);

digitalWrite(BUILTIN_LED, 0);

Serial.begin(115200);

WiFi.mode(WIFI_STA);

WiFi.begin(ssid, password);

Serial.println("");

// Wait for connection

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(".");

}

Serial.println("");

Serial.print("Connected to ");

Serial.println(ssid);

Serial.print("IP address: ");

Serial.println(WiFi.localIP());

if (MDNS.begin("thermostat")) {

Serial.println("MDNS responder started");

}

server.on("/", handleRoot);

server.on("/temp", handleGetTemp);

server.begin();

Serial.println("HTTP server started");

//Init DS18B20 sensor

sensors.begin();

sensors.requestTemperatures();

sensors.setWaitForConversion(false); //switch to async mode

pv, pv_last = sensors.getTempCByIndex(0);

ts = millis();

ot.begin(handleInterrupt);

}

void loop(void) {

new_ts = millis();

if (new_ts - ts > 1000) {

//Set/Get Boiler Status

bool enableCentralHeating = true;

bool enableHotWater = true;

bool enableCooling = false;

unsigned long response = ot.setBoilerStatus(enableCentralHeating, enableHotWater, enableCooling);

OpenThermResponseStatus responseStatus = ot.getLastResponseStatus();

if (responseStatus != OpenThermResponseStatus::SUCCESS) {

Serial.println("Error: Invalid boiler response " + String(response, HEX));

}

pv = sensors.getTempCByIndex(0);

dt = (new_ts - ts) / 1000.0;

ts = new_ts;

if (responseStatus == OpenThermResponseStatus::SUCCESS) {

op = pid(sp, pv, pv_last, ierr, dt);

//Set Boiler Temperature

ot.setBoilerTemperature(op);

}

pv_last = pv;

sensors.requestTemperatures(); //async temperature request

}

server.handleClient(); //handle http requests

}

Sample sketch implements simple http web server to be able control boiler using smartphone over WiFi.

Main web page shows current room temperature and allows to set up desired target temperature.

Current temperature constantly refreshes using asynchronous requests.

Sketch uses only two OpenTherm commands: to get/set boiler status and to set water temperature.

In main loop there is logic to read room temperature, calculate required boiler temperature using PID Controller,

and to set boiler temerature.

Serial Output:

...

Connected to Ihor Melnyk WIFI

IP address: 192.168.0.78

MDNS responder started

HTTP server started

sp=23.00 pv=22.69 dt=1.00 op=3.19 P=3.12 I=0.06 D=0.00

sp=23.00 pv=22.69 dt=1.00 op=3.25 P=3.12 I=0.13 D=0.00

sp=23.00 pv=22.69 dt=1.00 op=3.31 P=3.12 I=0.19 D=0.00

sp=23.00 pv=22.69 dt=1.00 op=3.38 P=3.12 I=0.25 D=0.00

Video:

To Buy Assembled OpenTherm Adapter + Shield (to stack WeMos D1 mini) please navigate to the Shop page or buy it here: